PRODUCT DESCRIPTION:

Nickel-Bond N2 Electrically Conductive Nickel Epoxy Adhesive, 1 Part, Heat Cure is a single component, heat curing, conductive epoxy polymer that was designed for ease in handling. This high performance conductive polymer cures quickly at elevated temperatures making it ideally suited for rapid Processing and assembly.

Nickel-Bond N2 Electrically Conductive Nickel Epoxy Adhesive, 1 Part, Heat Cure passes NASAs outgassing testing (ASTM E-595) and is listed in NASAs Outgassing Data for Selecting Spacecraft Materials list.

Nickel-Bond N2 Electrically Conductive Nickel Epoxy Adhesive, 1 Part, Heat Cure offers excellent mechanical, electrical, and physical properties at continuous operating Temperatures up To 175C. This versatile nickel conductive adhesive can be used for chip bonding in Micro and electronic hybrid circuit Fabrication. This unique conductive polymer also exhibits outstanding adhesion to a wide variety of substrates with good hot strength at intermittent temperatures up to 325C.

Nickel-Bond N2 Electrically Conductive Nickel Epoxy Adhesive, 1 Part, Heat Cure has also been used in microwave applications for EMI and FRI shielding, for assembly and repair of circuit boards and Electronic component manufacturing.

PRODUCT DESCRIPTION

| Base | Epoxy |

| Appearance | Grey |

| Cure Type | Heat cure |

| Substrates | Excellent choice aluminum, copper, magnesium, steel, bronze, nickel, kovar, ceramic, glass, phenolic and G-10 epoxy glass boards. |

| Viscosity @ 25 C cps | Soft Paste |

| Shelf Life | 6 months |

| Typical Application | microwave applications for EMI and FRI shielding, for assembly and repair of circuit boards and Electronic component manufacturing. |

| Benefits | passes NASAs outgassing

cures quickly at elevated temperatures

designed for ease in handling

offers excellent mechanical, electrical and physical properties |

CURED PROPERTIES:

| Hardness, Shore D | 88 |

| Volume Resistivity ohm-cm | 3.8 x 10-2 |

CURE SCHEDULE:

| 2 Hours | @ 125 C |

| 1 hour | @ 150C |

| 30 min | @ 175 C |

THERMAL CHARACTERISTICS:

| Thermal Conductivity, Btu/hr/ft2/F/in: | 10.1 |

| Operating Temp. Range, C | -55 to +175 |

NASA OUTGASSING RESULTS:

| TML (Total Mass Loss) | % 0.25 |

| CVCM (Collected Volatile Condensable Materials) | % 0.00 |

| WVR (Water Vapor Recovery) | % 0.07 |

GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

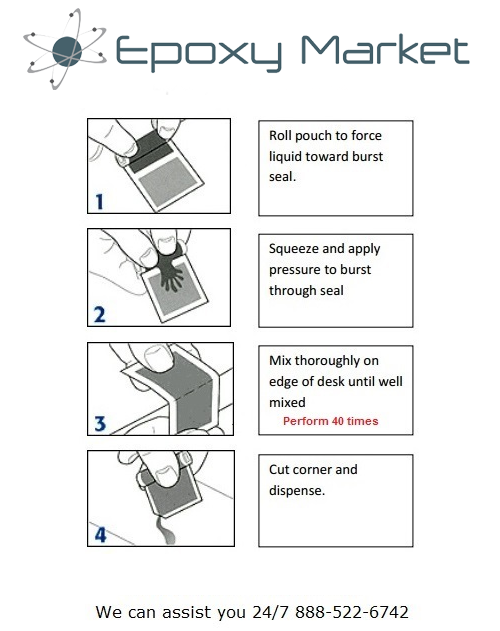

HOW TO USE:

1) Carefully clean and dry all surfaces to be bonded.

2) Apply Nickel-Bond N2 Electrically Conductive Nickel Epoxy Adhesive, 1 Part, Heat Cure completely mixed adhesive to the prepared surfaces, and gently press these surfaces together. Contact pressure is adequate for strong, reliable bonds; however, maintain contact until adhesive is completely cured.

3) Some separation of components is common during shipping and storage. For this reason, it is recommended that the contents of the shipping container be thoroughly mixed prior to use.

4) Some ingredients in this formulation provided may crystallize when subjected to low temperature storage. A gentle warming cycle of 52C for 30 minutes prior to mixing components may be necessary. Crystallized epoxy components do not react as well as liquid components and should be re-dissolved prior to use for best results.

AVAILABILITY:

This epoxy can be supplied in various different packages.

Loading... Please wait...

Loading... Please wait...