PRODUCT DESCRIPTION:

Fiber-Optic-Bond 25 Epoxy Adhesive, Fast Cure, Low Visc, 2 Part, Fiber Optic Connectors is a 8 minutes gelling epoxy recommended for use in fiber optic connectors, optical and industrial bonding applications.

Fiber-Optic-Bond 25 Epoxy Adhesive, Fast Cure, Low Visc, 2 Part, Fiber Optic Connectors is clear, two part system is easily mixed and used at room temperature. Fiber optic connectors can be polished in as little as 15 to 20 minutes for piston free assurance. The high bond strength of Fiber-Optic-Bond 25 Epoxy Adhesive, Fast Cure, Low Visc, 2 Part, Fiber Optic Connectors to glass, plastics, ceramics, metals and masonry allows it to be used in a wide array of applications including lens bonding, connector backfills, construction, component assembly and maintenance repair.

Fiber-Optic-Bond 25 Epoxy Adhesive, Fast Cure, Low Visc, 2 Part, Fiber Optic Connectors is low shrinkage epoxy, develops significant properties 1 hour after mixing. However, an extended cure of 4-6 hours at 25C is required for fully matured bonds.

NOTE: Fiber-Optic-Bond 25 Epoxy Adhesive, Fast Cure, Low Visc, 2 Part, Fiber Optic Connectors develops a high exotherm. Use immediately after mixing. The exothermic reaction begins within 2 minutes after initiating the mixing step, so have everything ready before mixing.

GENERAL PROPERTIES

| Components | 2 component - requires mixing |

| Mix Ratio by weight | 100:95 / Resin:Hardener |

| Benefits | Low viscosity

Fast Cure

Low shrinkage |

| Cure Type | Room temperature or Heat cure |

| Operating Temperature | -60 to 100 C |

| Typical Applications | Fiber optic assembly, multimode and single mode connectors, small potting and sealing applications |

| Appearance | Transparent / Clear |

UNCURED PROPERTIES:

| Viscosity @ 25 C | Resin: 9000cP, Hardener: 14000cP |

| Specific Gravity | 1.19 |

| Pot Life | 5 minutes |

CURE SCHEDULE:

| 24 hours | @ 25C |

| 1 hour | @ 60C |

CURED PROPERTIES:

| Glass Transition (Tg), ultimate, C | 40 |

| Hardness, Shore D | 75 |

| Tensile Shear, alum to alum, psi | 2800 |

| Volume of resistivity | 5.00e+11 ohm-cm |

| Dielectric Constant | 4.8 @ Frequency 1000 Hz |

| Dielectric Strength | 16.1 kV/mm 410 kV/in |

GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

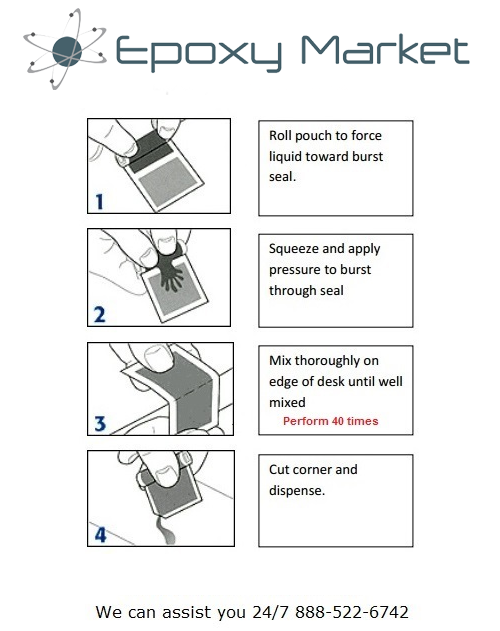

HOW TO USE:

1) Carefully clean and dry all surfaces to be bonded.

2) Apply Fiber-Optic-Bond 25 Epoxy Adhesive, Fast Cure, Low Visc, 2 Part, Fiber Optic Connectors completely mixed adhesive to the prepared surfaces, and gently press these surfaces together. Contact pressure is adequate for strong, reliable bonds; however, maintain contact until adhesive is completely cured.

3) Some separation of components is common during shipping and storage. For this reason, it is recommended that the contents of the shipping container be thoroughly mixed prior to use.

4) Some ingredients in this formulation provided may crystallize when subjected to low temperature storage. A gentle warming cycle of 52C for 30 minutes prior to mixing components may be necessary. Crystallized epoxy components do not react as well as liquid components and should be re-dissolved prior to use for best results.

AVAILABILITY:

This epoxy can be supplied in various different packages.

Loading... Please wait...

Loading... Please wait...